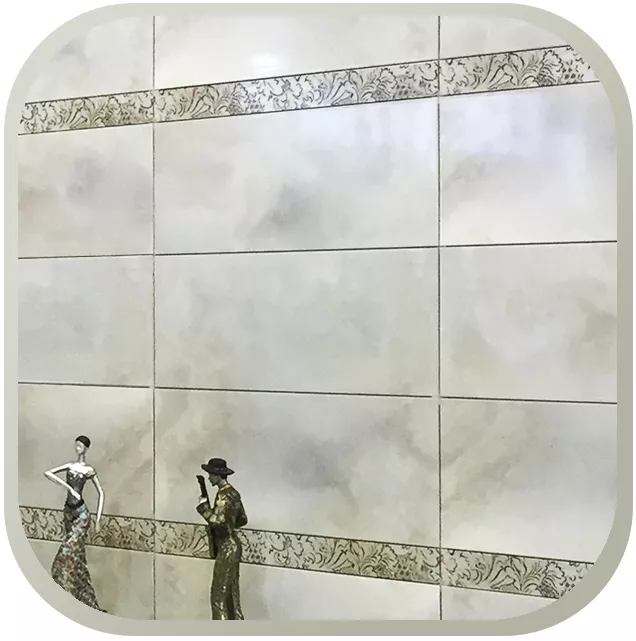

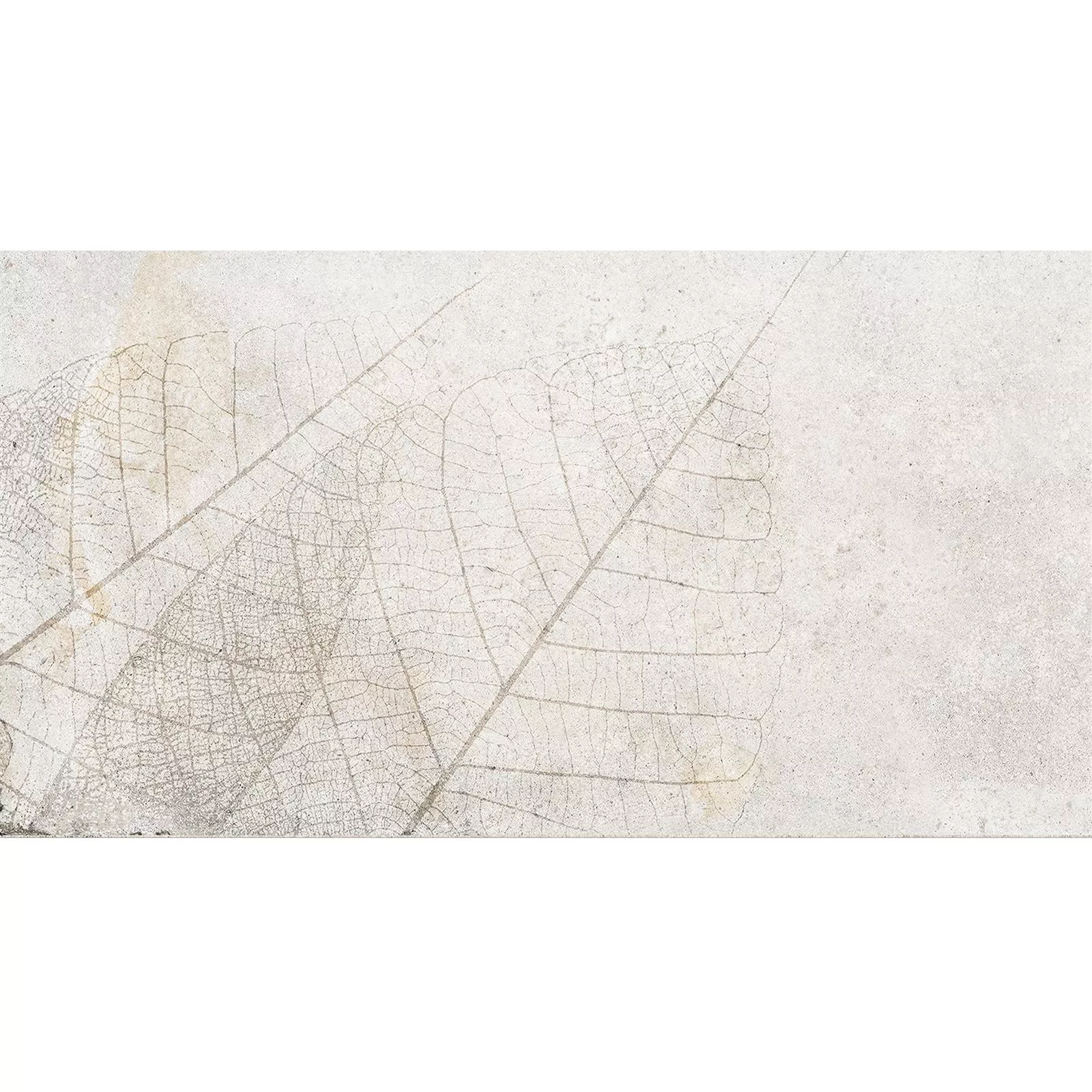

Wall Tiles Calibrated

Content: 1.62 Square meters (£22.51* / 1 Square meters)

Content: 1.62 Square meters (£21.41* / 1 Square meters)

Content: 1.44 Square meters (£24.08* / 1 Square meters)

Content: 1.44 Square meters (£24.08* / 1 Square meters)

Content: 1.08 Square meters (£23.03* / 1 Square meters)

Content: 1.44 Square meters (£22.23* / 1 Square meters)

Content: 1.62 Square meters (£21.41* / 1 Square meters)

Content: 1.62 Square meters (£21.41* / 1 Square meters)

Content: 1.44 Square meters (£19.81* / 1 Square meters)

Content: 1.44 Square meters (£19.81* / 1 Square meters)

Content: 1.35 Square meters (£34.27* / 1 Square meters)

Content: 0.18 Square meters (£113.44* / 1 Square meters)

Content: 0.18 Square meters (£113.44* / 1 Square meters)

Content: 0.18 Square meters (£113.44* / 1 Square meters)

Content: 0.18 Square meters (£113.44* / 1 Square meters)

Content: 1.26 Square meters (£28.94* / 1 Square meters)

Content: 1.62 Square meters (£20.31* / 1 Square meters)

Average rating of 5 out of 5 stars

Content: 1.26 Square meters (£26.82* / 1 Square meters)

Average rating of 5 out of 5 stars

Content: 1.26 Square meters (£26.82* / 1 Square meters)

Content: 1.26 Square meters (£27.60* / 1 Square meters)

Content: 1.26 Square meters (£26.82* / 1 Square meters)

Content: 1.125 Square meters (£20.52* / 1 Square meters)

Content: 1.125 Square meters (£20.52* / 1 Square meters)

Content: 1.125 Square meters (£47.95* / 1 Square meters)

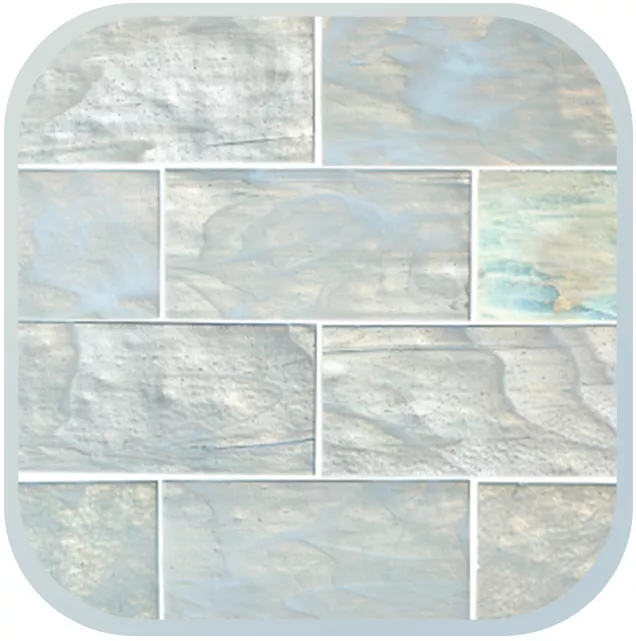

Calibrated over wall tiles

You see the words "fixed" and "calibrated" in product descriptions and packaging information, but do you know what those words actually mean? Both terms refer to the way manufacturers ensure tiles are consistently sized. Uniform tile sizes contribute to better installations.

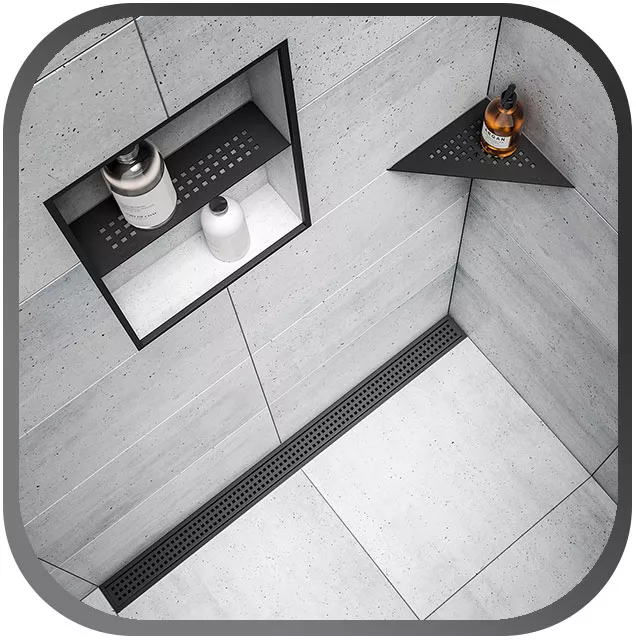

Calibration is the grading process that manufacturers can use to ensure that all tiles in packed boxes are dimensionally accurate. During the manufacturing process, unbaked ceramic tiles are almost the same size when they come out of the press, but baking causes the tiles to shrink, perhaps by slightly different percentages from piece to piece. Through calibration, manufacturers sort tiles by finished size. Calibrated tiles are aligned to match the caliber range specified by the manufacturer. These tiles have to meet stricter dimensional change requirements than natural tiles , but do not have machined edges. Tiles are usually grouped into two to four different calibers, according to the industry's strict sizing requirements. Calibrated tiles are usually allowed to deviate by more than +/- 0.5 from the average size of the corresponding caliber, but no more than +/- 2 mm. Calibrated tiles may be available at prices suitable for more budget conscious projects.

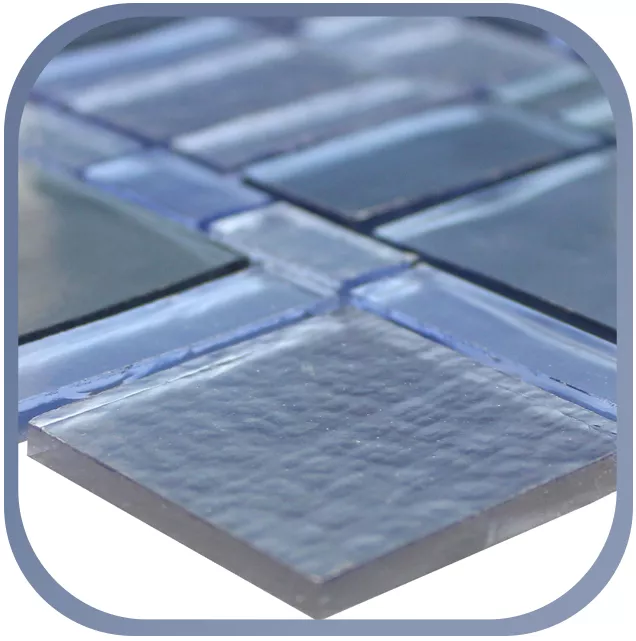

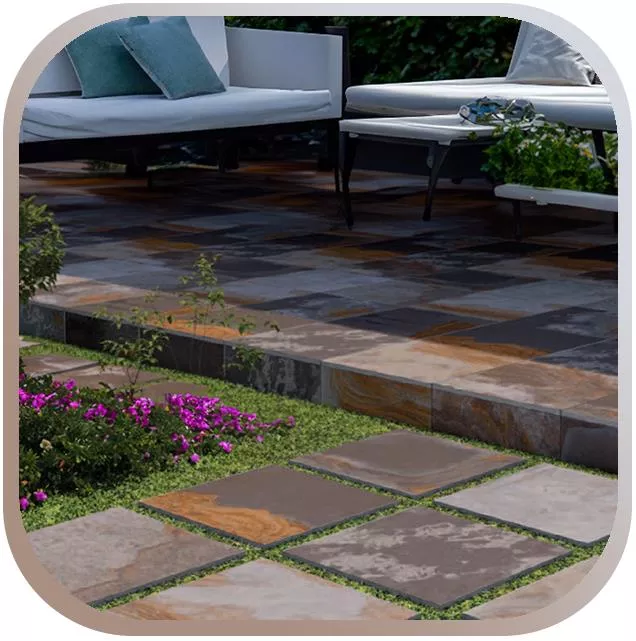

Rectified tiles are fired and then sanded to size. This is done to meet exacting standards in terms of dimensional consistency. The edges of the rectified tiles are precision machined and machined to ensure consistency to allow greater precision of sizing from piece to piece in a product line. The uniformity of rectified tiles eases installation and can simplify tile patterns and unique tile designs. The full edges of rectified tiles may allow for smaller joints (a minimum of 3mm joint is recommended) compared to the edges of non-rectified tiles. If thin grout lines are desired for an installation, it is recommended to specify rectified tiles.

Be sure to find out if your tile has been straightened or calibrated to get the best possible installation results. Mosafil prioritizes full disclosure and product education, so we give you the details you need on all product information, whether printed or online.

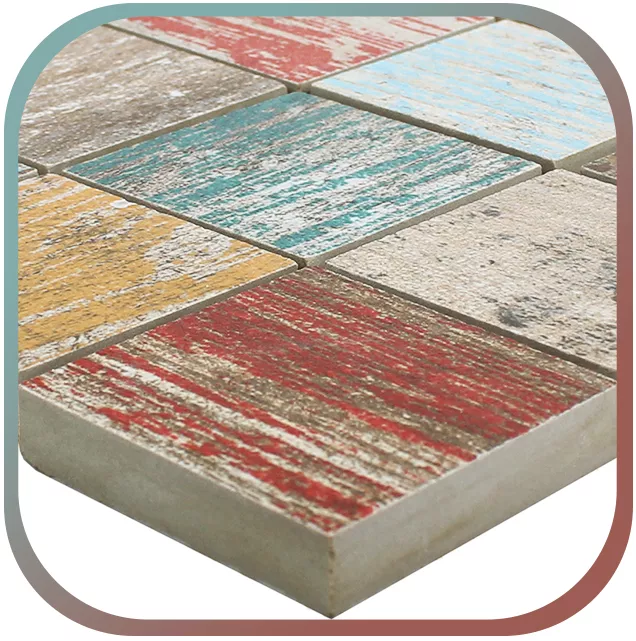

The calibrated tile is cut before going through the firing process. The tile is cut into neat squares and placed in the oven. The only problem with this method is that the tile shrinks at different rates. Often homeowners want minimal grout, but minimal grout is often not recommended by the manufacturer (the tile does not sit flush). Calibrated tiles have become the industry standard tiles. Calibration is the process of fine-tuning tiles to the desired size. The tile is usually cut so that the edges are formed at a 90 degree angle. However, other production dimensions are also theoretically possible. Natural stones and ceramic tiles are usually calibrated. For projects on a tighter budget, calibrated tiles may be available at a lower cost. If the calibration is done accurately, the joints between the tiles may be too small. However, this is not always desirable or necessary, for example, in the case of polygonal tiles laid in a mosaic-like manner.

Rectified tile is pre-cut, fired and then trimmed. This process minimizes the size differences from tile to tile. Tile siding can give a nice finish, but the conditions of the subfloor (where you are installing the floor) are more important. The soil must be well prepared to get the expected results. Rectified tiles are ceramic or porcelain tiles that have been cut or sanded to full size using diamond saws. By trimming the tiles you can give them a sharp 90 degree edge. This makes it easy to lay tile by tile and the joints are very narrow, which is popular in the flooring industry. They are called rectified tiles because the technique actually corrects the dimensions of the tiles. The result of firing or burning a ceramic tile is never accurate or predictable. The tiles may look the same when they enter the oven, but the change in humidity during the baking process is uncontrollable. This causes the tiles to shrink and warp significantly. Ceramic and porcelain tiles always differ slightly in shape and size when they come out of the kiln. Rectified tiles are often slightly larger than they should have been before going into the kiln. Therefore, they can be reduced to full size after burning. The "correction" procedure requires grinding the tiles or cutting the tiles with diamond saws. Rectified tiles have machined edges to achieve a more precise area size. This is called edge treatment as it is only applied to the edges of the tile. Rectified tiles are always marked with the word "Rettificato" as a sign of quality. It's just a different process that results in a different look: fine, smooth and precise grout lines.

Buy Calibrated Wall Tiles online

Calibrated tiles are often available in the same colours, shapes and patterns as rectified tiles but at a lower price. Rectified tiles are slightly more expensive to buy. Rectified tiles tend to cost a little more as they are a little more complex to produce than non-rectified tiles of a similar quality. Calibrated tiles require larger joints. Calibrated tiles require larger grout lines to keep the tiles looking more even, which reduces the smooth, flawless appearance of your tiles.

Rectified tiles allow for a thin grout line. Compared to the edges of non-rectified tiles, the full edges of rectified tiles can allow for smaller bond lines. If thin grout lines are desired for an installation, it is recommended to specify rectified tiles.

30x60 glossy white rectified wall tiles and 30x60 white matt calibrated wall tiles are often preferred tiles in our catalogue.